Pool Pump Basics: What Does A Pool Pump Consist Of

2023.06.30

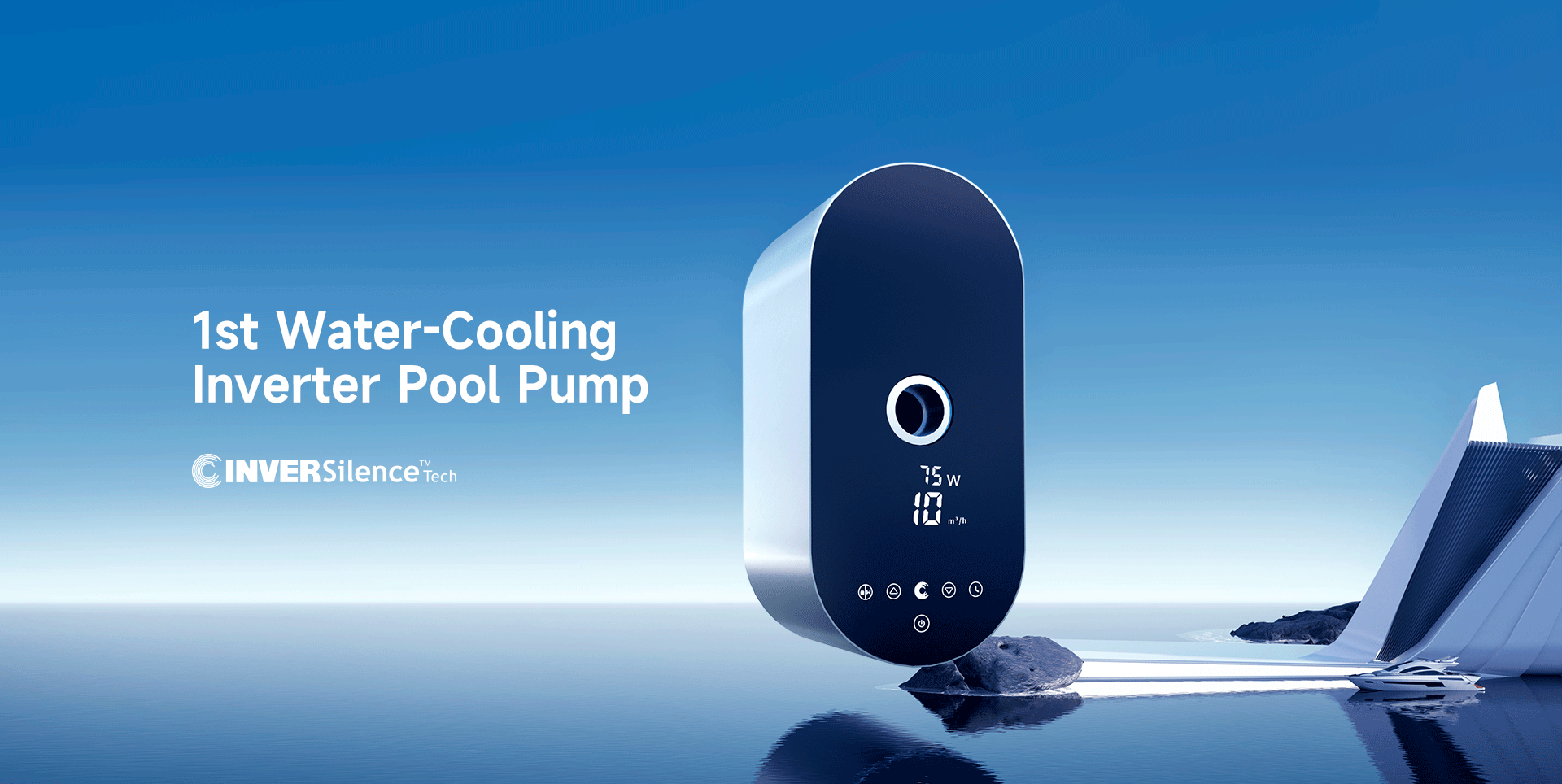

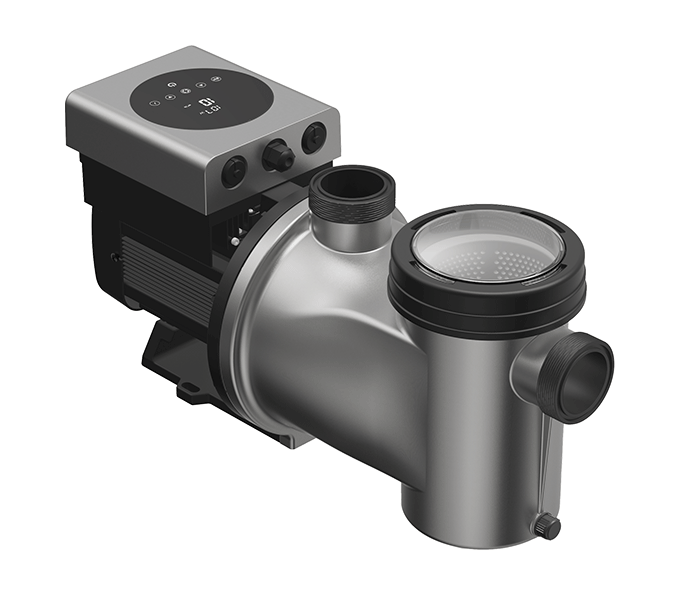

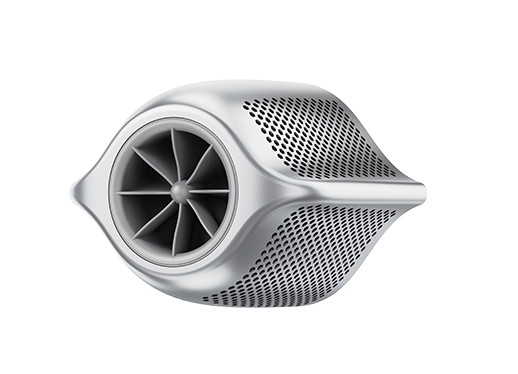

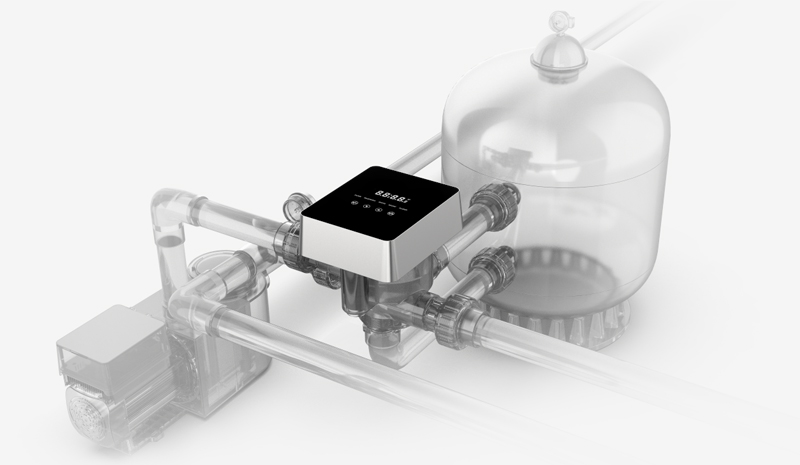

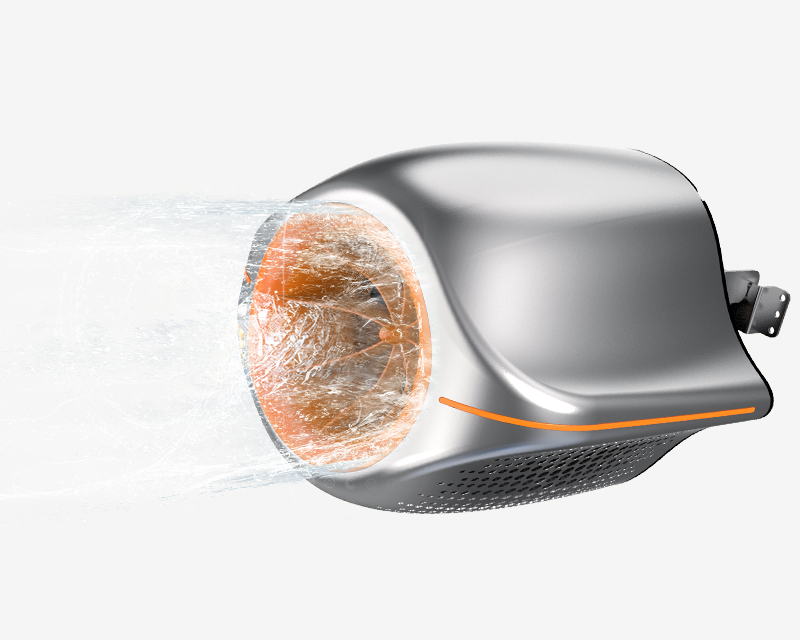

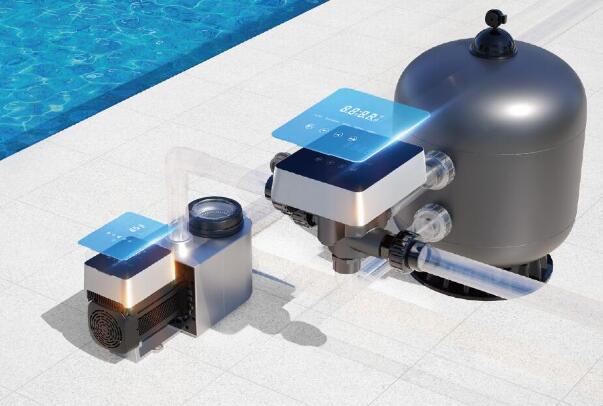

A pool pump is the most vital part of a swimming pool, the heart of any pool circulation system. The pool pump pulls the water out of the swimming pool, pushes it to other equipment for treatment, filtration, and heating, and returns clean, healthy, and warm water to the swimming pool. Today, more pool families are applying inverter pool pumps because inverter technology brings increased energy efficiency, enhanced silent effect, and a new intelligent operation. Let’s now go over the crucial parts of inverter pool pumps. By understanding the various components of a pool pump and how they work together, we can better manage the pump for optimum performance and longevity.

06.30.2023